Can lights often exhibit noticeable air leakage gaps, to the extent that light can be observed from the living space in the attic. Our approach involves sealing these gaps using a combination of caulk and a foam board cover. Recessed lights require extra caution since they are typically not IC rated due to the heat they generate. To address these penetrations, we either replace the lights with IC rated ones or utilize a rock wool cap, which offers fire retardant properties and an additional insulation layer around the recessed light penetration.

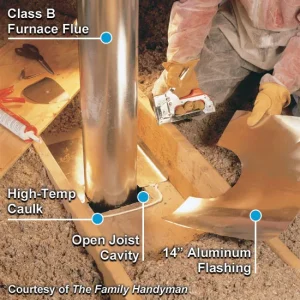

When air sealing a chimney or flue, we employ a combination of techniques. First, we use high-temperature caulk or sealant to seal any gaps or cracks between the chimney or flue and the surrounding structure. Then, we install a chimney cap or flue damper to further prevent air leakage and improve energy efficiency.

Sealing duct leaks is crucial for maximizing energy efficiency, as the average home can lose 20-30% of HVAC energy through these leaks. By addressing gaps around duct boots with Great Stuff spray foam, we effectively prevent conditioned air from escaping into the attic and unconditioned air from entering the living space.